Until the late 1800's, the miller and baker enjoyed a close relationship. Initially the two professions started out together. In Egyptian times it was more a labour force that would grind the wheat, and then bake the different varieties of breads. Most likely, it was the high priest who directed the whole procedure, having slaves do most of the work. The Romans, in their organized, systematic way, would set up flourmills, and large ovens in central locations to ensure that the whole population could be fed. This provided a stable diet for the Roman population. Until the late 1800's, the miller and baker enjoyed a close relationship. Initially the two professions started out together. In Egyptian times it was more a labour force that would grind the wheat, and then bake the different varieties of breads. Most likely, it was the high priest who directed the whole procedure, having slaves do most of the work. The Romans, in their organized, systematic way, would set up flourmills, and large ovens in central locations to ensure that the whole population could be fed. This provided a stable diet for the Roman population.

The typical cone shaped mills with the oven beside it have been dug up in Pompeii, and we can clearly visualize the process and the importance baking bread had had at the time. Field ovens and mills also went wherever the Roman army would be stationed, or wherever their excursions led them. It was imperative to feed their massive armies and keeping them strong, and in good health promoting success in the next battle.

Already at that time the first independent bakers formed and set up shops in the center of larger cities. Initially the baker concentrated on baking bread to guarantee that none went hungry in the growing population. The rise of a great empire depended on a stable food supply. Transporting the grain over large distances was not feasible at the time, so the bakers used locally grown grains. This limited the availability of what bakers had at their disposal. The growing conditions could fluctuate widely, and the challenges facing the bakers in those days, cannot be imagined. Our flours are blended and come  from far distances to ensure good quality, and consistent results. The grain of the Romans and subsequent medieval times was harvested and stored in granaries. The millers would grind grains on a daily basis, having Demand dictate their quantities. The reason was that the flour would go rancid, spoiling it. This is caused by the oxidization (contact of air) that the wheat germ was exposed to during grinding processes, making the flour spoil in a very short time. Storage of milled flour for any length of time (more than a few days) could not be done. This necessitated that the baker needed to use freshly ground flour at all times. Until the technology was developed (roller mills) in the middle of the 19th Century (the Industrial Revolution), this was the procedure. from far distances to ensure good quality, and consistent results. The grain of the Romans and subsequent medieval times was harvested and stored in granaries. The millers would grind grains on a daily basis, having Demand dictate their quantities. The reason was that the flour would go rancid, spoiling it. This is caused by the oxidization (contact of air) that the wheat germ was exposed to during grinding processes, making the flour spoil in a very short time. Storage of milled flour for any length of time (more than a few days) could not be done. This necessitated that the baker needed to use freshly ground flour at all times. Until the technology was developed (roller mills) in the middle of the 19th Century (the Industrial Revolution), this was the procedure.

Due to the Industrial Revolution (when huge machinery was the fashion), the roller mill was developed. It essentially, as the name implied, rolled the wheat kernel, cracking the shell. This process eventually led to the complete separation of the wheat germ and bran from the endosperm. The fats that are present in the germ could not spoil (go rancid) the flour anymore, making the flour storable in vast quantities, for long periods of time (months). Our modern grain mills are very sophisticated machinery, and can include 30 to 40 separate stages for the grain to go through until the different specialized flours emerge at the end. Through blending we can tailor the flour to specific baked goods, giving us characteristic baking qualities.

The millers in the old days could only try by sifting the flour, to eliminate some of the bran, but there were not ways to separate the germ at the time. The millers in the old days could only try by sifting the flour, to eliminate some of the bran, but there were not ways to separate the germ at the time.

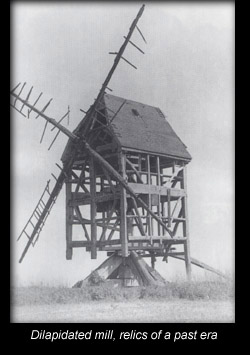

In Europe the close relationship between the miller and the baker can still be seen and felt more because of their long history together. Many small towns in Europe still have old flourmills visible in the countrysides: remains from a past where it was mandatory for successful towns to have their own miller and baker.

White bread has its origin in Roman times: it was reserved for the upper class. The whiter/lighter the bread, the better it was supposed to be. There was even a law prohibiting common folk from eating this 'pure' type of bread. The flour used in this bread was sifted extensively, eliminating all bran and wheat germ ingredients, basically what we do in today's modern milling practices. The masses and the gladiators were fed with brown bread, heavy with bran, and the wheat germ.

As long as the flour was milled freshly and the baker was competent in using his sourdough culture, the resulting bread would be a delicacy even in our days. Due to the many influencing factor of the time, consistent quality was lacking. With the introduction of packaged (baker's) yeast, coupled with the new milling machinery and technology, the results became much more consistent.

The Industrial Revolution would facilitate the production of machinery that allowed the refining processes of sugar beet, and vegetable oils in large quantities. The availability of sugars and fats (oils) at affordable prices, and the newly developed flours, led to many new bakery products, especially in the field of pastry and cake items.

The small flourmills that were propelled by either wind or water that supplied us in times past are slowly disappearing. There are some that are restored, but mostly for nostalgic reasons; there are few bakers that would dare to bake with freshly ground flour. The small flourmills that were propelled by either wind or water that supplied us in times past are slowly disappearing. There are some that are restored, but mostly for nostalgic reasons; there are few bakers that would dare to bake with freshly ground flour.

A handful of mega mills, powered by electricity, are churning out all of the flour needed for the population of today. The craft of the miller has been reduced to a few people. After the two world wars, the introduction of the mega bakery supplying bread for people for hundreds, and even thousands of miles around has become the norm. Distance and transportation don't matter anymore.

The ever ingenious and clever businessmen have developed many convenient modern baking methods that include mixes, and easily frozen (bake off) goods. These items now dominate the commercial baking industry. You can read more about this in "The Modern Baker".

The challenges of the miller and the baker have changed dramatically since the Industrial Revolution. The profession of the miller has now been reduced to just a few mass producers, and the bakers are losing their identity as well. The traditional ways are becoming extinct. When we reflect on how our past has led to this present, it becomes obvious that not all inventions have been positive. However, this should not discourage us, but we, with our modern technology, can change and make things better, if we realize what we need to do.

Our contributions to a better food staple are our sourdough breads. The wheat germ that is so cleverly separated in modern mills is kept intact with our natural stone milling process. In the past, this wheat germ used to be fed to livestock, but we are finally starting to recognize this mistake. The combination of using an active bacterial culture and mostly the whole grain (including the germ) in the production of our bread, ensures a well balanced and nutritionally valuable product. |